We love new challenges and for the past 30 years we’ve encountered a wide variety of memorable projects that we are proud of. Take a look.

SYSTEMS + HARDWARE DESIGN

A big challenge on a tight deadline.

The Challenge:

Our client was asked last minute to demonstrate their Neural Network Accelerator interfaced to a new MCU, running audio and video based recognition. The project had to be completed within eight weeks, in time for the Consumer Electronics Show in Las Vegas for a scope of work that normally takes 3 months.

The Solution:

RDP&A designed an interface PCB and had it fabricated within a week. We wrote low-level “bring up” code to verify robust communication between the devices, developed real-time double buffering code to minimize data transfer overhead, wrote efficient YUV to RGB video conversion routines, designed the data format between MCU and host computer, and co-developed the presentation code to run on the host. Specialties involved:

Efficient signal processing and data transformation

Hard real-time data streaming

Bare-metal device drivers

“Rob and his team were amazing in helping us with this impossible task! Our demo went was impeccable! Thank you Rob!”

The Neural Network Accelerator demos worked flawlessly at CES.

The Result:

SYSTEMS + HARDWARE DESIGN

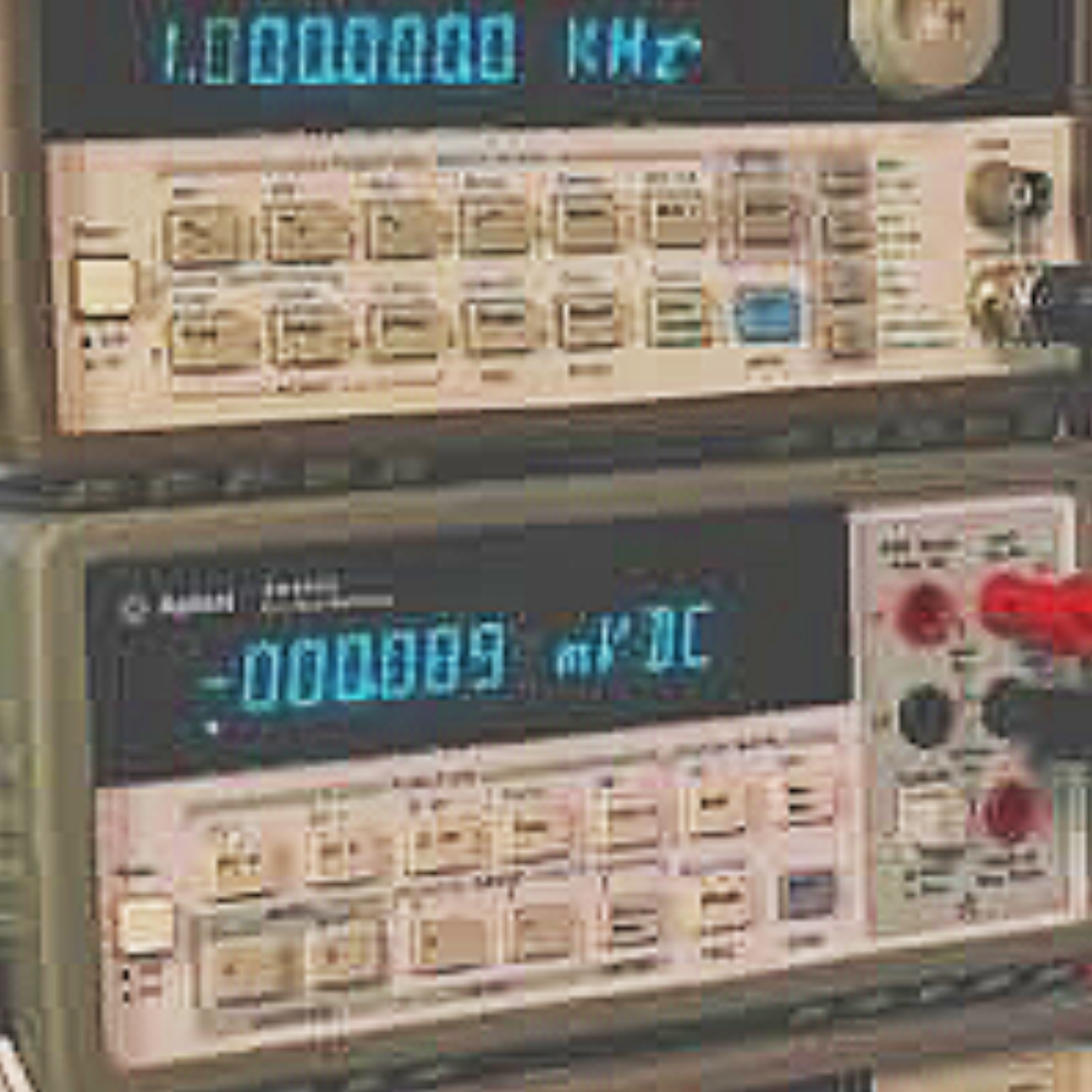

Femto-amperes and rapid iteration

The Challenge:

Our client had designed the analog front-end for a sensitive current measurement prototype. But it was unproven and required precisely timed digital control to realize its full potential.

The Solution:

Because the analog front end was a new design, we worked closely with the client as the design went through many iterations. We suggested firmware techniques to simplify the analog hardware and increase its accuracy, often delivering updates within a matter of hours. Specialties involved:

Close collaboration and rapid iteration with hardware designers

Rapid bring-up and validation of new hardware

Characterizing and compensating for analog noise and nonlinearities

Replacing analog components with built-in MCU modules in order to reduce BOM cost and improve performance.

“Rob and his team were amazing in helping us with this impossible task! Our demo went was impeccable! Thank you Rob!”

A precision instrument with reduced parts count and increased accuracy.

The Result:

SYSTEMS + HARDWARE DESIGN

A complete condition-based monitoring system

The client was bootstrapping a startup that focused on condition based monitoring of rotating devices (fans, compressors, pumps, etc), and needed a portable demonstration system that instantly conveyed the company’s value proposition.

The Challenge:

RDP&A designed and built a complete condition-based monitoring solution that displayed the status of a variety of battery powered fans in real-time (“normal”, “off-balance”, “obstructed airflow”, “bad bearing”, “under speed”). The solution’s hardware included 3D printed accelerometer housings, custom PCBs to interface to a Raspberry Pi, an elastomer base for the fans to prevent external interference. Embedded software computed the real-time cepstrum of the accelerometer data, comparing its Euclidean distance from a set of known signatures and transmitting the most likely signature to the host. The host software in turn ran a micro-server that displayed diagnostic info about the fan being measured. Specialties involved:

“Soup to nuts” design from sensors to user presentation

Custom 3D printed sensor housings

Low-overhead, bespoke signature analysis algorithms designed to match the capabilities of the target processor

Designed and wrote Python-based RESTful server to display results.

The Solution:

The Result:

With the help of the demo, the startup raised funding, acquired its first customers and is now an industry leader in its space.

“Rob and his team were amazing in helping us with this impossible task! Our demo went was impeccable! Thank you Rob!”